Sustainability in Crane Manufacturing

The construction industry is a cornerstone of global development but is also one of the largest consumers of energy and producers of greenhouse gas emissions. As the effects of climate change become more pronounced, the push for sustainability within this sector grows stronger, with crane manufacturing playing a crucial role in this transformation.

Why Sustainability Matters in This Industry

Cranes are essential for the development of infrastructure and buildings, facilitating the movement and assembly of large materials. The environmental impact of these operations is significant, with cranes traditionally powered by diesel engines and consuming vast amounts of energy. The urgency to reduce carbon footprints and mitigate environmental degradation drives the need for sustainable practices in crane operations.

The adoption of sustainability in crane manufacturing and operations can drastically reduce harmful emissions and lead to a more resource-efficient production process. This shift is not only beneficial for the environment but also aligns with global movements toward sustainability, helping companies stay competitive and compliant with emerging regulations.

Let’s Talk About Sustainable Practices

Below, we explore some key practices each business can implement in their worksites to make each build as environmentally efficient as possible.

Energy-Efficient Designs

Manufacturers are now focusing on creating cranes that are more energy efficient. This includes the integration of technologies like regenerative braking systems, which reclaim energy, and more efficient hydraulic systems designed to reduce overall power consumption.

Use of Renewable Energy

Implementing renewable energy sources such as solar panels or wind turbines to power crane operations can significantly decrease the dependence on fossil fuels, fostering a cleaner energy transition.

Innovative Fuel Solutions

Shifting from diesel to hybrid or fully electric cranes offers a substantial reduction in greenhouse gas emissions. Moreover, advancements in engine technologies are enhancing fuel efficiency, contributing further to eco-friendly initiatives.

Maintenance and Operations

Ensuring that cranes are well maintained not only prolongs their lifespan but also ensures they operate at optimal efficiency. This practice minimizes unexpected downtimes and reduces waste, resulting from inefficient energy use or the premature disposal of machinery.

Eco-Friendly Material Handling

Adopting sustainable practices in material handling—focusing on reducing waste, reusing materials, and recycling—helps diminish the environmental footprint of construction activities significantly.

Benefits of Sustainable Crane Practices

Reduced Environmental Impact

By lowering emissions and using cleaner energy sources, sustainable crane operations contribute to less environmental degradation and a healthier planet.

Cost Efficiency

Energy-efficient cranes tend to incur lower operational costs due to reduced fuel consumption and government incentives for green technology adoption, leading to significant cost savings over time.

Enhanced Industry Reputation

Companies that prioritize sustainability are viewed more favorably by clients, partners, and stakeholders, enhancing their marketability and building trust in their commitment to environmental stewardship.

Regulatory Compliance

With many regions tightening environmental regulations, integrating sustainable practices ensures that companies remain compliant, avoiding potential fines and legal issues.

Long-term Sustainability

Sustainable practices enhance the durability and functionality of cranes, promoting a longer lifespan and reducing the frequency and cost of replacements.

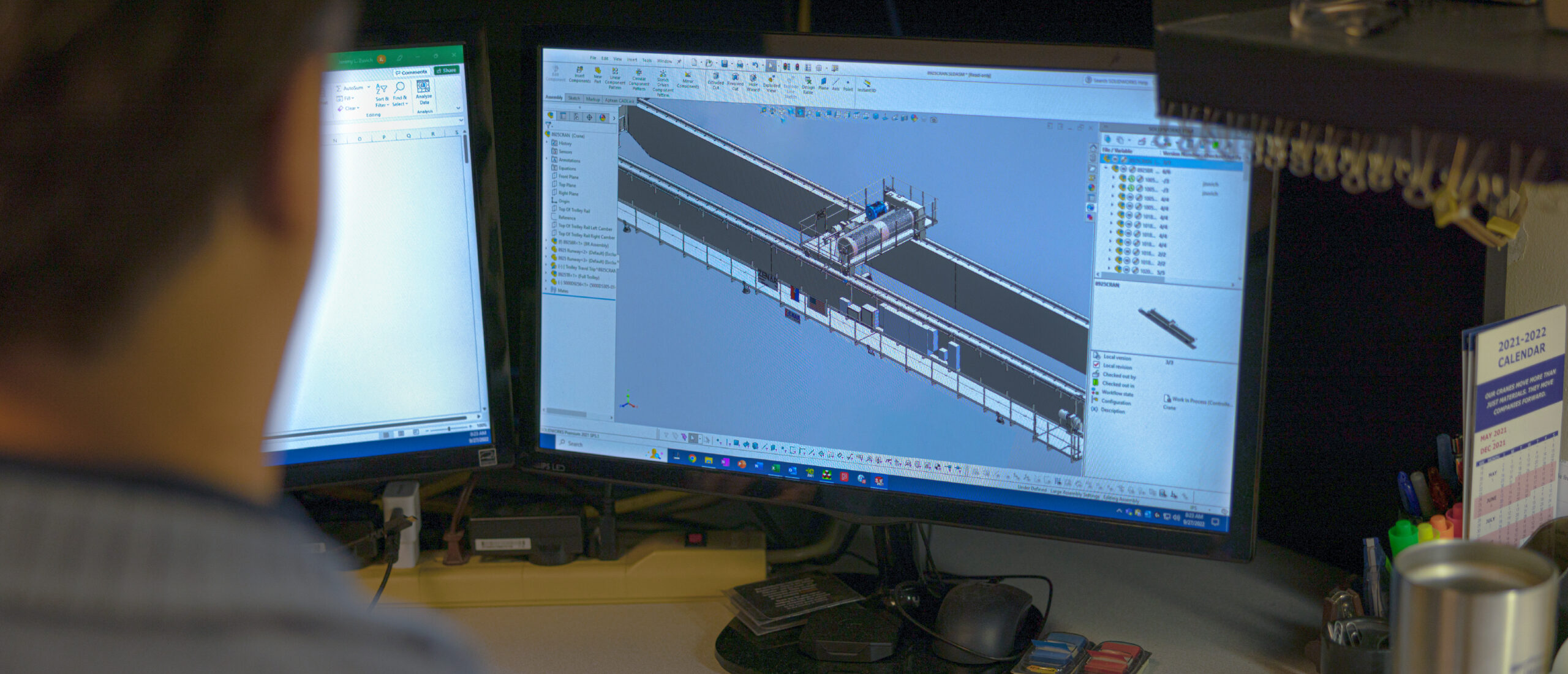

Experience the Zenar Difference

The construction industry’s future strongly intertwines with sustainable practices, particularly in crane manufacturing and operation. Companies like us offer cutting-edge solutions to ensure that cranes not only meet the current industry standards but also contribute to a more sustainable and environmentally conscious construction environment. Adopting these practices not only helps protect our planet but also paves the way for the future of construction, where sustainability is at the forefront of every operation.

From our family-owned roots to our commitment to American-made quality, we bring a personal touch to each project. Our expertise, innovative solutions, and unwavering dedication to customer satisfaction set us apart as a leader in the industry.

Elevate Your Operations with Zenar Crane

Implementing an overhead crane facility can transform the efficiency, safety, and productivity of your operations. With Zenar Crane’s custom solutions and turnkey services, you can build a facility that meets your specific needs and supports your business goals. Experience the difference that our American-made, family-owned expertise can make for your operations. Contact us today to get started on your journey to enhanced material handling and operational excellence.

Ready to revolutionize your operations with a custom overhead crane facility? Contact Zenar Crane today to learn more about our turnkey crane solutions and how we can help you optimize your material-handling processes. Visit our website to explore our range of products and services, and discover why we are the trusted choice for businesses across the nation.

Read

More

Articles

How Zenar Cranes Are Designed for Safety & Reliability

When it comes to heavy lifting, safety and reliability aren’t just important—they’re absolutely non-negotiable. In an industry where machinery routinely operates under extreme conditions, Zenar Cranes have earned their reputation as trusted workhorses thanks to their robust design and advanced features.

8 Ways to Avoid Costly Crane Repairs

Overhead cranes play a pivotal role in the efficiency of industrial operations, serving as critical equipment in the movement and lifting of heavy materials. However, when these cranes falter, the financial repercussions from repairs, lost productivity, and enhanced safety risks become significant.

Troubleshooting Techniques for Overhead Crane Electrical Problems

Nestled within the bustling heart of the industrial sphere, overhead cranes stand as monumental testaments to human engineering and ingenuity. These mechanical behemoths are indispensable in a myriad of sectors, from construction to manufacturing, playing a pivotal role in the lifting and transportation of heavy materials. Yet their pivotal role comes with its set of challenges, especially when it comes to maintaining their electrical integrity.